Miticides 2011

Miticides 2011

Randy Oliver

ScientificBeekeeping.com

First published in American Bee Journal February 2011

Colony health and production these days is largely a function of varroa levels in the hives—the more mites, the more problems. It is no longer a matter of simply knocking the mites back once a year with a “silver bullet”—it is becoming increasingly clear that mite levels must be kept low all season. Here is a status report on the current state of miticides.

Varroa has settled in to roost, and beekeeping is clearly no longer the same as it was a mere twenty years ago! The mite has completely changed the bee/virus dynamic, leading to unacceptable yearly colony losses. What the most successful commercial beekeepers have found is that they can minimize losses by keeping tabs on varroa levels, and never allowing them to rise above a few per percent (mites per hundred bees) at any time of the year.

Any reader of my articles is aware that I take a future view, and strongly promote the use of mite resistant bee stocks (such as the VSH and Russian stocks developed by the ARS), and of biotechnical methods. I personally walk the walk, and gave up synthetic miticides over ten years ago. However, to keep mite levels in check, I find that I still require the periodic use of some sort of treatment. I personally choose to use an assortment of “natural” treatments, but there is no reason to exclude the judicious use of synthetic miticides.

There is a strong trend among recreational and sideline beekeepers away from synthetic miticides, motivated largely by the desire to engage in “chemical free” beekeeping. However, you cannot truly call yourself a “beekeeper” if your bees keep dying on you! There is a big difference between “natural” beekeeping and simple colony neglect. I suggest that all beekeepers familiarize themselves with the pros and cons of the available miticides, should the need arise to save a colony from an ugly death. You can visit ScientificBeekeeping.com for my in-depth articles on mite management and details on miticides.

As I speak with commercial beekeepers across the country, I find that they, too, largely share a similar sentiment against synthetic miticides, although for more practical reasons—they are concerned about comb and honey contamination, colony and queen health issues, and the lack of viable alternatives to the currently popular chemicals.

The comb contamination issue is finally coming to the fore, with recent research, most as yet unpublished, indicating that miticide residues (often coupled with pesticide contamination) in the combs wreak havoc with bee brood and colony immunocompetence. Indeed, one of our most eloquent commercial beekeepers, John Miller, recently stated at the California state convention that we beekeepers have been “poisoning the womb of the hive.”

Beekeepers keep pleading for effective new mite treatments that are safe, that won’t contaminate the honey, are harmless to the bees, easy to use, that will have a long effective life, and that cost only pennies. Dream on! We are our own worst enemy, as we tend to misuse or misapply every miticide at our disposal, and then use it without rotation until it is no longer effective, or until our combs become hopelessly contaminated.

The good news is that the future is looking a bit brighter, but it is going to require smarter management on our part—including using mite-resistant bee stocks, constant monitoring of mite levels, practicing integrated pest management, the use of more expensive miticides, and not thinking that we can get by doing the same danged thing year after year!

I’ll give you the rundown on treatments from old to new, but first let’s look at the main modes of action by miticides against our uninvited hive guest, the varroa mite. In general, mite treatments can be placed into one of three different categories:

- Short-acting: one-shot hits which target only the phoretic (hitchhiking) mites (and miss the mites hiding in the brood). Examples would be oxalic acid, SucrocideTM, “mite wipes,” TakticTM in oil, the new HopguardTM, low-dose essential oils, and powdered sugar dusting. Mite levels often quickly rebound after treatment when more mites emerge from the brood, so it generally takes multiple treatments to actually bring mite levels down.

- Extended Release: those products whose mode of action spans more than one mite reproductive cycle (~12 days), thus killing phoretic mites as they emerge from the safety of the brood cells. The release of the miticide is extended by formulating it into a plastic strip, or by mixing it into a carrier. ApistanTM, Checkmite+TM, HivastanTM, ApivarTM strips, or Taktic dissolved in shortening fall into this category. Unfortunately, the problem with the synthetic miticides is the issue of comb contamination due to their lipophilic property (they dissolve readily into beeswax) and stability; amitraz being the exception (amitraz and coumaphos may, however leave residues in honey).

- Fumigants: those which evaporate at broodnest temperatures. These include essential oils, notably thymol, and formic acid. The problem with this mode of action is that it is temperature dependent (not too hot or too cool), are often disruptive to colony behavior, may cause the queen to cease egglaying temporarily, may kill some brood, and in the worst case may cause queen loss. However, these treatments have the great advantage in that they are composed of “natural” components, and evaporate or degrade relatively quickly, leaving few residues in the combs or honey.

Synthetic Miticides

The synthetic miticides are manmade chemicals, generally effective at very low concentrations. They have the huge advantage in that if they are already used as agricultural pesticides, then they have existing tolerance levels in food, and are inexpensive to manufacture.

Synthetics also have the advantages of exhibiting, when mites are first exposed to them, high “margins of safety”—i.e., the ratio of how toxic they are to mites compared to bees (for example, a margin of safety of 100:1 would mean that it takes only 1/100th as high a dose to kill mites as it does to kill bees). The higher the margin of safety, the more leeway you have with dose and application method.

One drawback of synthetics is that since their mode of action targets a single biological mechanism, mites have demonstrated the ability to quickly evolve resistance. As the mites become resistant, that shifts the margin of safety down, until it approaches 1—the point at which is takes as high a concentration to kill a mite as it does to kill a bee, at which point the chemical would then be worthless for varroa control in a hive.

Apistan™

Fluvalinate was the original “silver bullet” against mites, first in the form of off-label use of Mavrik TM, soon followed by the famous Apistan plastic strips. Apistan was the treatment by which all others were subsequently compared—what with 99% mite kill, a margin of safety of about 800:1, and being extremely nontoxic to humans. Fluvalinate does have some issues with comb contamination and can build up to levels that may negatively impact bees, queens and particularly drones.

We had a good run with Apistan/Mavrik, but after several years, the only mites left were resistant to the product (even increasing the dose by more than 100 times would no longer kill them). However, if you haven’t used it for some years, it may again give good mite control (once). If you should use it, be sure to test your bees afterward to confirm that it did indeed work!

TYPES OF PESTICIDE REGISTRATION |

|

| Section 3 Regular Registration | We only have a few miticides that are fully registered for use in hives: Apistan, Apiguard, Mite Away II, Sucrocide |

| Section 18 Emergency Exemption from Registration | A state can request an emergency exemption from federal registration in order to allow the use of an unregistered pesticide in an emergency situation there is no feasible alternative to the exemption. Checkmite+, Hivastan, and Apilife Var are allowed in various states under Section 18 exemptions (but no longer in California) |

| Section 24(c) Special Local Need (SLN) Registration | A state may register an additional use of a federally registered pesticide on a food/feed crop for which a tolerance has been for use in a special local need situation. A special local need could include a new pest, or a new application method or timing. Registration of Hopguard under SLN has been requested by about a half dozen states, and of MAQS in three. |

| Trade Offs | The EPA will only allow a small number of Section 18 exemptions for any particular use. Control of varroa is considered such a use. In order for a state to get an exemption for a new product, it has to give up a previous Section 18 treatment. Unfortunately, this often limits our available spectrum of legal varroacides. |

Checkmite+™

This follow up to Apistan contains the organophosphate coumaphos, but mites very quickly developed resistance. That, coupled with its detrimental effects upon queens and brood, and serious long-term comb contamination, have caused it to lose popularity. However, it is currently the only chemical registered for in-hive treatment against small hive beetle (it must be applied carefully to minimize transfer to the combs).

Amitraz

Amitraz was effectively used when we first got the mite in the U.S., but there were soon resistance issues, and it kinda dropped from the scene. It had a resurgence when coumaphos began to fail, and quickly became the current mainstay of U.S. commercial operations as an off-label use of the ag product Taktic. Lately, amitraz, incorporated into Apivar strips, has been registered for use in some areas of Canada, and has been very effective, so long as the strips are properly applied. There has been a section 18 application filed for Apivar that is still awaiting EPA response.

Amitraz has the distinct advantage of rapid degrading in the hive, so that there don’t appear to be major comb contamination issues with it (although its degradation products linger). Note that in the U.S., there is no longer an allowable tolerance level for amitraz in honey. We’d have to get Apivar registered to reinstate a tolerance level.

Predictably, the clock appears to be ticking on the effectiveness of Taktic, with beekeepers reporting that the “old doses” are no longer resulting in the sort of mite kill that they used to expect. Many are ramping up the dose, which portends that it won’t be long until mites are laughing at the chemical, with the usual devastation soon to follow.

Hivastan™

This next generation miticide was a bugger to develop, due to adult bee toxicity issues. Hivastan has yet to be enthusiastically embraced by beekeepers. A chill reverberated through the industry shortly after its release when one large beekeeper had an unfortunate and costly experience when the active ingredient (fenpyroximate) apparently interacted during cool weather with a fungicide from almonds. However, there are commercial guys who are using it successfully, generally applying it at less than label dose in order to minimize the amount of adult bee kill.

Mann Lake’s Products in the Pipeline

I gotta hand it to Mann Lake—where there is a need for a beekeeping product, this employee-owned company invests the time and money to get it to market. I spoke with Stuart Volby about two new miticides that they are currently in the process of registering. Stuart pointed out that all existing agricultural miticides have already been tested against varroa, and either aren’t suitable, or are tied up in other uses. Luckily, with his inside connections to the chemical/pharmaceutical industries, he has access to thousands of unregistered potential products that have yet to find a use. Some of these have already gone through human toxicity trials, but fell through development for other uses; if they showed promise as a miticide, Stuart was interested. Two compounds stood out.

Both of the new compounds (still kept tightly under wraps) are “brand new,” meaning that they have not been previously registered for agricultural use. That means that they can’t be granted a Section 18 Emergency Exemption by the EPA, since they had not been previously listed in association with a food product. Therefore, Mann Lake must pursue the more difficult Section 3 registration.

Both products have very high “margins of safety”– about 300:1 for the first product, and something in the range of 1000:1 for the second. The first product is being produced in conjunction with one of the pharmaceutical giants, and will be applied in a biodegradable strip (Stuart’s got a patent on such strips; so you won’t need to pry out spent plastic strips!).

Neither product exhibits noticeable brood toxicity. But they are both lipophilic, so will likely wind up in the combs to some extent; Mann Lake has not yet completed testing for residue longevity. How soon will they hit the market? The process moves frustratingly slowly, but the first product should be out soon.

“Natural” Treatments

The “natural” treatments have the distinct advantages of already being present in the hive (in small amounts) as natural components of honey, of rapidly degrading biologically, and of being well accepted by consumers. Their modes of action are generally more complex, so that varroa appear to be less able to evolve resistance to them.

The flip side of natural treatments is that they don’t have very wide margins of safety (typically in the range of say 2:1 – 4:1), so that the beekeeper must apply them properly and with care. Issues of temperature and placement within the hive are often critical.

Formic Acid

This natural component of honey is widely used in Europe, but is awkward to work with, as it is problematic to maintain the release of its vapors at optimal levels. Many beekeepers use liquid formic on absorbent meat tray pads (“mite wipes” [1]), but unless the treatment is repeated at least 4-6 times, the results may be iffy. The labor costs for that many treatments is prohibitive, and in the real world, most beekeepers simply don’t complete the entire course.

Better control was to be had with either of two extended-release products: MiteAway IITM pads or Bill Ruzicka’s MiteGoneTM wafers [2]. The former had the advantage of being both registered, and not requiring the handling of bulk liquid acid, however, MiteAway II pads are no longer being manufactured, to be replaced by a new product, which I will describe shortly.

Another method that works well is the “flash treatment,” as independently developed by Dr. James Amrine [3] and Jean-Pierre Chapleau [4]. The flash treatment can actually penetrate the brood cappings and kill mites (and perhaps pupae) beneath the cappings.

Formic acid has a long history of success at killing mites, and there are no signs yet of varroa developing resistance to it. A major beauty of formic is that it leaves no residues, and that it is a natural component of honey. Its main drawbacks are safety and convenience issues with handling the liquid form. Formic has the additional benefit of also killing tracheal mites, and disinfecting combs (to some extent) of chalkbrood and nosema.

Essential Oils/Thymol

The essential oils are popular with the “natural” crowd, as they are food-grade products. Although several essential oils look promising in the lab, only thymol has consistently proven its worth in the field. Although thymol can be applied as pure crystals, or incorporated into shortening patties, it is probably wiser to trust one of the two registered products: Apilife VarTM or ApiguardTM.

I personally prefer the Apiguard gel, due to its effectiveness and ease of application, and since it appears to be less disruptive to the colony, but Api Life Var has many satisfied users. I also find that the product works better for me if I apply only a half dose (25 g, adjusted for colony strength) in the middle of the broodnest (Fig. 1). The middle of the broodnest is kept at constant temperature by the bees, which eliminates the wide swings in evaporation rate which may happen when the gel is placed under the hive cover, as per label directions.

I’ve tried to pinch pennies by making my own thymol patties, but haven’t found that it’s worth it. Apiguard gel in bulk is convenient to use (Figure 1), and worth the money, in my humble opinion. It has become my summer mainstay. By the way, I’ve done the math, and one 25 g dose of Apiguard contains about as much thymol as does a pound of fresh thyme herb.

Figure 1. Here’s a tip for applying Apiguard thymol gel: Cut the cards that come with the product in half lengthwise, then use the card to scoop up the gel and toss it onto the top bars in the middle of the broodnest. This photo shows exactly 25 g of Apiguard, but I adjust the dose relative to colony size (be sure to measure carefully).

Oxalic Acid

What a huge disappointment our pesticide regulatory system is in that oxalic acid has not yet been registered for use in this country (it is now scheduled in Canada). I’m not much of a fan of oxalic vaporization (I nearly coughed myself to death when I played “guinea pig” and intentionally inhaled some vaporized fumes), but the “dribble” method (in which it is applied in sugar syrup) is extremely safe to the beekeeper, effective, and cheap. It is my fall/winter treatment of choice when colonies are broodless, but can also be used for a quick mite knockdown during summer.

Be sure to follow mixing and application instructions to the letter [5]—you can easily hurt the bees if you have a sticky trigger finger! I also did the math on this: one application of oxalic dribble contains about as much oxalic acid as does a small serving of spinach (and will help your bees be strong to the finish!).

Products Soon to be Released

Hopguard™

Registration is already in place in several states for this new product, soon to be available from Mann Lake (perhaps by the time you read this article). It currently has a Section 18 (emergency) registration as a “reduced risk biopesticide,” with the hope that it will eventually receive full Section 3 registration.

This new treatment is unlike anything else on the market. It consists of cardboard strips immersed in a dark brown liquid, which are applied dripping wet, straddled over the top bars. Although the product is considered to be safe to humans, you will want to wear disposable nitrile gloves, since it is a bit messy to apply.

Hopguard was introduced by BetaTec® Hop Products, a company that develops applications for hop products outside of the brewing industry. The thick brown liquid (the technical term is “gloopy”) is composed of “hop beta acids”—which are one of the components that give hops their aroma (as opposed to their bitterness, which is a property of the alpha acids). BetaTec had previously found that beta acids were effective against spider mites, so varroa were a natural extension. The company also found that the compound prevents the growth of AFB and EFB bacteria in the lab, and has filed two patents that I’ve found–for control varroa, AFB, EFB, chalkbrood, SHB, and wax moth.

Beta acids are a GRAS (Generally Recognized as Safe) food additive, and have been safely consumed in beer for centuries (it is the alcohol in beer that causes problems). They degrade readily in the environment, and don’t appear to cause any comb contamination, nor get into the honey as long as they are placed only in the brood chamber. However, due to their effectiveness as bactericides and fungicides, more testing needs to be done with regard to their effect upon beneficial bee microbiota (I asked Dr. Gloria DeGrandi-Hoffman, and she says that the Tucson Lab is looking into this).

Hopguard was developed by USDA-ARS Tucson and Beltsville; Fabiana Ahumada has been the principal research lead. It’s been tested in a few states, and the results look promising. It has a very short-acting effect, as it only works as long as the strips are wet on the surface. The main mite drop is over by Day 3, depending upon temperature and humidity, and it has no residual effect (Fig. 2).

Figure 2. A Hopguard strip after three weeks. It has dried out, and the bees will soon complete the process of removing the cardboard.

I’ve tried the product, and it has no apparent negative effect on the bees, brood, queen, or colony behavior. The ARS data indicate that it can drop the majority of phoretic mites. So Hopguard could be useful as a periodic “knockdown” treatment to help prevent mite buildup. It may be especially useful as an approved food-grade treatment that could buy you some time while the honey supers are on (it doesn’t taint the honey if only applied in the brood chambers).

Hopguard does not kill the mites in the brood, so I wouldn’t count on it alone to bring down a heavy infestation during the summer. However, it may prove to be very effective when colonies go broodless in late fall, or during dearth. Hopguard could also have “niche” uses, as in the case of one California trial in which a queen breeder needed a quick mite knockdown that wouldn’t affect the queens or drones.

Treatment requires two strips per brood chamber full of bees, and the cost will be about $30/50 strips; so total cost will be about $2.40 for a strong double deep.

I have not yet done the calculation to determine how many beers you’d have to drink to consume the equivalent amount hops acids as found in a Hopguard treatment.

Mite Away Quick Strips™ (MAQS™)

What the industry is crying for is a “dream” miticide that effectively kills most of the mites in a hive with a single treatment, and that is safe, legal, can be used over a wide range of temperatures, is unlikely to have resistance develop, will not contaminate combs or honey, and that can be used even when honey supers are on. That is quite a wish list! The amazing thing is that a new product soon will be on the market which appears to meet all those criteria!.

The product is called the MiteAway Quick Strip, developed by beekeeper David VanderDussen. My hat is off to David for sheer perseverance! He’s been working to bring beekeeper-friendly, single-application formic products to market for some 15 years, and deserves a big “thanks!” from our industry.

It’s been a long slog to come up with a formic product that is safe and easy to apply, yet would control the release of the volatile vapors. Dr. Medhat Nasr developed the first version of the fiberboard pad in a ziplock bag in 1996, and ARS researchers filed a patent for a silica gel pad in 1997, the same year that David brought the original Mite Away pad to market. But the breakthrough moment came when David hit upon using chemistry to develop a formate ester that would more slowly release the vapors, culminating in the improved Mite Away II pad in 2004.

David VanderDussen, beekeeper and developer of the Mite Away Quick Strip.

But the MiteAway II pad still had drawbacks: inconsistent efficacy, broodnest interruption, and the danged “rim” necessary for application. No one liked the long treatment period nor the need for the return trip to remove the pads and rim.

David has solved all of the above problems by developing a gel strip with the consistency of soft gummy candy. It is composed of plant sugars, and wrapped in a tissue paper-like product that controls the rate of vapor release (Figs. 3 and 4). I am very impressed by how user-friendly the product is to handle!

Figure 4. Now sniff! The formic acid smell is as intense from the ants as it is from a MAQS! I had a heckuva time taking this photo with one hand while the ants were biting me! Be careful not to inhale an ant!

The strips are thin enough to fit between the brood chambers, which puts the formic right where it can do the most good (and where the temperature is moderated by the bees). The bulk of the treatment effect occurs over the first three days, after which the rate of evaporation drops off greatly (although one can still smell formic acid in the used pads even after three weeks).

Birth Control for Varroa

OK, the pads are handy to use, but the real beauty is that by putting them smack dab in the center of the broodnest, the fanning by the bees drives the vapors right through the brood cappings where it can kill the tiny, soft skinned, pale male and developing female mites. This was David’s “aha!” moment—if you can kill the male mites before they can mate with their sisters, then even if some females emerge, they won’t be able to reproduce!

Surprisingly, the fumigation is able to kill not only the delicate males, but even most of the hard shelled females in the brood, generally without killing many bee pupae! (Expect some brood kill, which is a reasonable price to pay for good varroa control). And then the formic acid residues simply evaporate from the hive! [6].

Testing MAQS in California

Does MAQS simply sound too good to be true? Well, did to me, too! So I begged David to allow me to test it in California (following other trials conducted in Hawaii, Florida, Texas, France and Ontario in 2009). I intentionally allowed mite levels to build up in two experimental yards, and waited while we arranged permission for a test. Finally, David happened to be passing through California on November 1st, and came over to help me to place the strips.

I ran this trial to see whether MAQS could bring down appreciable mite infestations in a typical fall situation, so I intentionally included only colonies that had what I considered to be substantial mite levels–some well above the safe fall threshold (in my opinion, fewer than 6 mites in a wash). Mite levels were dropping due to reduced fall broodrearing; however, there was sealed, and generally some open, brood in every hive, so the trial indeed tested whether MAQS could actually kill mites under the cappings. All hives were double deeps with 10 frames, of various strengths from weak to strong. Hives were mostly on screened bottoms, so I slid in Masonite inserts to close off the screens on a portion of them.

We applied the strips in the afternoon at about 65°F (18°C); bees were flying freely (see Figs. 5, 6, and 7). I was struck by how little formic acid smell there was (less than with Mite Away II pads), and can attest to the safety to the applicator at that temperature. The fumes apparently sunk downward off the strips, since the bees immediately fanned and moved out of the way as we placed the strips over the frames. We gave the control hives sham treatments of folded copy paper.

In the second yard I treated some hives with Apiguard thymol gel for comparison—about 25 g on a 3×5 card placed in the center of the broodnest. Note that both of these fumigation treatments work best when applied in the center of the broodnest, as opposed to under the hive cover.

Update Jan 2016: I take the above back–Apiguard thymol gel works very well when applied to the top of a double-deep colony, with an added 1.5-inch rim to allow the vapors to disperse.

Figure 5. Top bars of the bottom brood chamber before applying the strips. Air temperature is about 65°F (18°C).

Figure 6. David’s hand applying the first strip. Note how quickly the bees move away.

Figure 7. This photo, taken seconds later, shows how the bees quickly crawl away from the fumes. Surprisingly, they soon become accustomed to them, and will go about their business in a formic atmosphere that would make your eyes burn! This is the proper placement of the strips—centered over the cluster with a space between them, each one shoved clear to the outside so as to fumigate the outer comb. There’s a a rather corny application video on the Web [8].

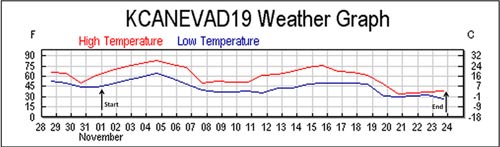

I monitored the hives for the next few days, and could smell formic acid at the entrances, but did not observe any notable adult bee mortality. The daily high temperatures during the critical first four days of outgassing climbed from 65 to 85°F (18 to 30°C) (Fig 8). However, I could still smell formic acid at the entrances after a week. I checked a few hives at Day 13—the bees appeared to be ignoring the strips. The weather turned cold (snow) toward the end of the trial, causing the bees to move into tight cluster.

Figure 8. Daily high/low temperatures (from a nearby weather station) during the trial. The weather during the first 4 days nearly covered the entire recommended range for use of the product, which is from 50-92°F (10-33°C).

Mites started dropping immediately after treatment, and by the second day there was considerable drop on the sticky boards beneath the screened bottoms. I was not interested in those counts, however—what I wanted to know was what the mite infestation of the bees would be after a complete brood cycle, so that I could see if any mites in the brood survived and emerged. I was able to take samples on Day 23, when the weather cleared (Fig. 9).

Figure 9. Actual mite counts from ~300 bees from the broodnest, alcohol wash, at start and end of the trial (divide the numbers by 3 to obtain percent infestation; the highest initial infestation was 24%). The blue bars indicate initial mite infestation; the red bars final infestation, which was lower in all colonies except one of the controls, in which the mite level went up. In several of the treated colonies,

Figure 9. Actual mite counts from ~300 bees from the broodnest, alcohol wash, at start and end of the trial (divide the numbers by 3 to obtain percent infestation; the highest initial infestation was 24%). The blue bars indicate initial mite infestation; the red bars final infestation, which was lower in all colonies except one of the controls, in which the mite level went up. In several of the treated colonies,

Mite levels were reduced to below economic threshold levels in every single one of the treated hives (whether strong or weak), especially in the MAQS treated on solid bottoms; levels remained unacceptably high in all but one control hive. I was surprised by the good showing by the Apiguard 25 g treatment, despite the cool weather in the latter part of the trial; however note that by chance most of the Yard 2 hives started with lower mite levels.

At the endpoint (Day 23, at which all samples were taken home and blind counted), some colonies had clustered above the strips, but most clusters were either in the bottom box, or spanned boxes. The results indicate that movement of the cluster did not negatively affect the efficacy of MAQS treatment. Broodrearing had been curtailed in all groups due to environmental conditions, but was not noticeably less in the treated groups. Some colonies had started the trial small and with fairly high mite counts, so it was not surprising to still see some with rather small clusters.

All colonies appeared to be behaving normally at the end of the trial (although inspection was done on a cool day). We spotted most of the queens as we took samples, and a number of colonies had small patches of sealed brood, and some even had a bit of young brood, indicating that the queens had resumed laying midway through the trial (if they had ever stopped at all). There was no sign of excessive queen loss; the queens in the treated hives with brood looked fat and healthy; queens without brood looked expectedly small, but their behavior appeared normal. Weak colonies appeared to tolerate the strips well, despite the label recommendation of a 6-frame minimum. We observed a freshly emerged supersedure cell in one MAQS treated hive and in one very weak control colony, but this was not unexpected with the high mite levels at the start of the trial.

A New “Silver Bullet”?

The take home from this trial was that MAQS were a very effective “clean up” treatment for colonies with substantial mite infestations prior to winter. I will continue to monitor the hives until they go to almonds.

I gotta say, I’m pretty impressed by MAQS! They performed well in this trial despite there being a wide range of temperature. I did not sample brood to confirm mite kill (it was confirmed in previous trials), but if any mites had survived, they should have been evident at the end of the trial.

It looks like David’s claims are well founded—MAQS could be the Silver Bullet that we’ve been waiting for! We will soon have a treatment that you can pop in, even during a honey flow (treatment doesn’t affect the honey [7]), and then simply walk away (the strips are biodegradable, and the bees will eventually remove them; we found that they can also be easily flipped off the frames with a hive tool). I’ve heard from some Hawaiian beekeepers that the dosage may need to be adjusted in very hot weather, as the full treatment “knocked back” colonies, but that is the normal sort of trial and error process that beekeepers are used to with any new product.

The strips unfortunately don’t come cheap—David suspects that a pair will retail in the $4-$5 range. Those of you who are gasping for breath should keep in mind the great labor savings of such an effective treatment! (I figure that it costs me a buck per hive just in labor every time I apply a treatment). Commercial beekeepers may find MAQS especially handy for August treatment while the last honey supers are on. I suspect that one fall treatment in cold-winter areas would give you varroa control until spring, or a few months protection at other times of the year (and possibly some control of nosema as a side benefit [9]. Beekeepers who eschew synthetic chemicals could rotate MAQS with Apiguard, and perhaps an oxalic dribble, for a total cost of less than $6 per year to keep mites down! For those running mite-resistant stock, one treatment a year might (big caution here) do it.

There you have it. I would greatly appreciate feedback from commercial beekeepers anywhere on what is working, what is not, and tips and tricks for best application of any of the products.

Acknowledgements

Thanks to David VanderDussen, Stuart Volby, and Dr. Eric Mussen (who does not endorse any off-label use of any product) for fact-checking and helpful comments to the manuscript.

References

[1] http://www.honeybeeworld.com/diary/2000/diary101000.htm#Formic

[2] www.mitegone.com

[3] http://ento.psu.edu/directory/duv2/vanEngelsdorp_et_al_flash_formic_2008.pdf

[4] (Broken Link!) http://www.apinovar.com/articles/flash.en.html

[5] Google “the learning curve part 3”

[6] http://www.miteaway.com/html/what_is_maqs.php).

[7] Mitchell, D and D VanderDussen (2010) Mite-Away Quick Strip™ Mid Honey Flow Efficacy Trial. ABJ 150(5): 487-489.

[8] http://www.miteaway.com/html/videotutorials.php

[9] http://www.miteaway.com/assets/multimedia/MAQS_Intro.wmv