The Varroa Problem: Part 1

January 29, 2017

The Varroa Problem: Part 1

Randy Oliver

ScientificBeekeeping.com

First Published in ABJ in November 2016

Legend has it that King Sisyphus was condemned to the maddening task of being forced each day to roll a huge boulder to the top of a hill, only to watch it roll back down again, and then to repeat this for eternity. Sisyphus was being punished for having the hubris to think that he was more clever than the gods.

In modern times, we beekeepers are cursed with the maddening task of killing varroa mites, only to see them build up again before the season’s end. Perhaps we are being punished for having the hubris to think that we are cleverer than Mother Nature.

A Fusillade of Parasites

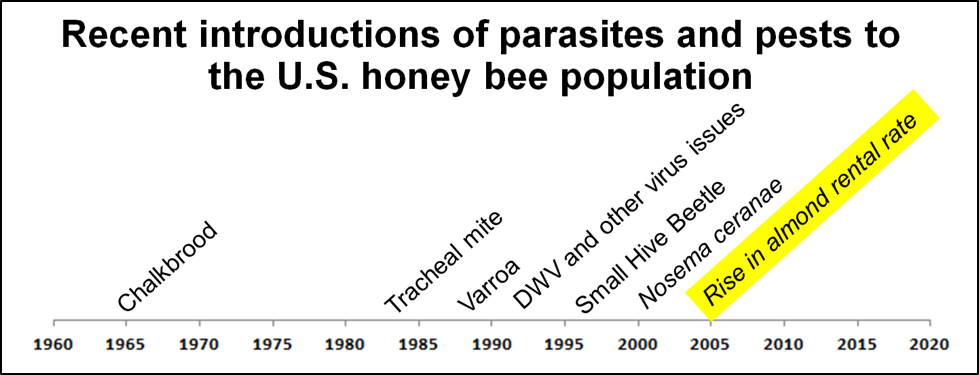

Varroa destructor began its invasion of the honey bee population of North America in the late 1980s, midway in a calamitous fusillade of inadvertent parasite introductions (Fig. 1).

Varroa first showed up in my California colonies in 1993 [1]. I’ve now been keeping bees with varroa for as nearly as long as I kept them without, and have been part and party to watching beekeepers being forced to evolve their practices in order to deal with the mite and its associated viruses.

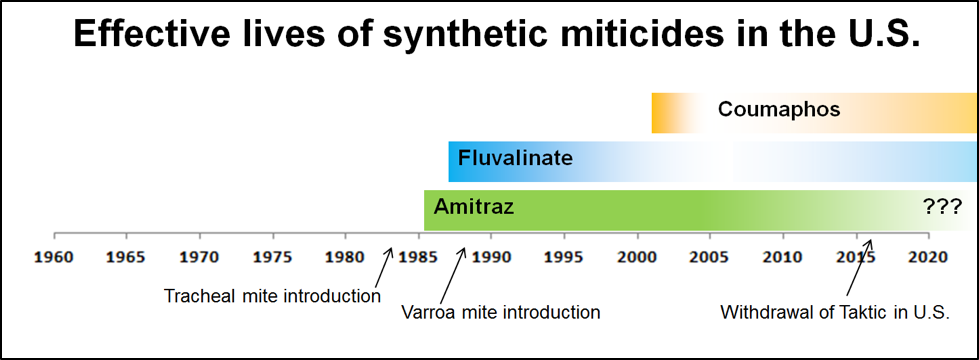

Over the past 23 years, varroa at first devastated my operation [2], then became easy to manage with Apistan® strips, then regained the upper hand as fluvalinate failed, then succumbed for a short while to coumaphos. At that time I lost faith in synthetic miticides [3], and since the year 2000 have wrestled with learning to manage the mite by other methods and treatments (thymol, formic, and oxalic acid).

My own choices aside, the miticide amitraz saved our commercial industry. In the early 2000’s, when mites quickly developed resistance to coumaphos, for a short while there was no legal effective synthetic miticide. Amitraz was a miracle and a savior, and rapidly adopted by many.

As DWV evolved, the better beekeepers began recognizing that even fairly low mite levels hurt the productivity and survival of their colonies. Many of the most successful commercial beekeepers have now long depended upon regular applications of amitraz to keep mite infestation rates below the 1% level for most of the season, and the bee industry has rebounded in recent years.

A Looming Problem?

But good things rarely last forever. As with other synthetic miticides limited to a narrow mode of action, repeated and unbroken use of a product applies a strong selective pressure for the mite to evolve resistance. Fluvalinate, for example, began to fail after about six years, and only by ramping up the dose to extreme levels were beekeepers able to extend its effective life (Fig. 2).

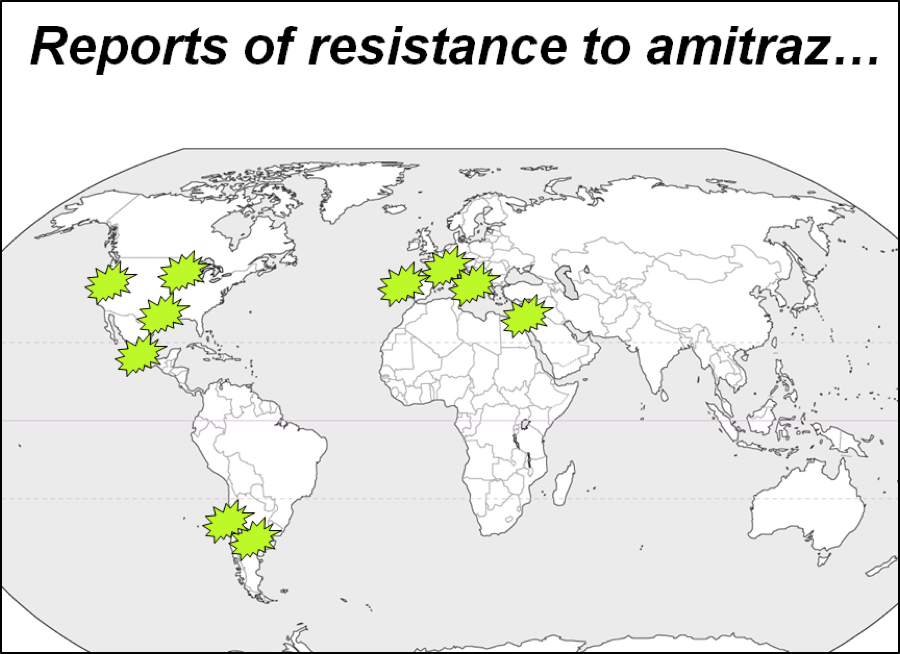

In California, coumaphos failed completely after only three seasons of use. Amitraz, to my great surprise, has been continually (and quite successfully) used by a many beekeepers now going on 15 years (and for some, 30 years). But evolution appears to be finally catching up with amitraz (Fig. 3.), and there are indications that things may be about to change…

In California, coumaphos failed completely after only three seasons of use. Amitraz, to my great surprise, has been continually (and quite successfully) used by a many beekeepers now going on 15 years (and for some, 30 years). But evolution appears to be finally catching up with amitraz (Fig. 3.), and there are indications that things may be about to change…

Here in California, beekeepers who used to be able to control mites with two applications of amitraz per season are now forced to apply the treatment 6-10 times. This may forebode…

Here in California, beekeepers who used to be able to control mites with two applications of amitraz per season are now forced to apply the treatment 6-10 times. This may forebode…

A New Era in Mite Management?

Unfortunately, as far as I can tell, there are few promising synthetic miticides in the process of registration or development. It costs a lot of money to bring a product to market, so no manufacturer is much interested in registering a product for varroa if beekeepers can use a cheaper agricultural formulation off label. And then there is the issue of effective life of a product—if mites develop resistance in a few years, the manufacturer may not recoup his development and registration costs.

So that leaves us with several options:

- Ramping up the dose of amitraz applied. This is unlikely, due to the unavailability of product other than the pricey Apivar® strips, and would only accelerate the selection for resistant mites. For a stunning illustrative video on the development of resistance, see [4].

- Reuse of fluvalinate, coumaphos, or registration of synthetics not previously registered in the U.S. [5].

- Development of new synthetic miticides with different of action.

- Development of botanicals, behavioral disruptors, RNAi products, or other biologicals [6].

- Use of the (often more expensive) registered organic acids or thymol (Apiguard®).

- The final solution–adoption of varroa-resistant bee stock.

The Evolution of Mite Management

When varroa first hit our bees, they were absolutely unprepared for this novel vector of viruses. Previous to the introduction of the parasitic mites to the North American bee population, the primary mode of transmission for viruses was via the fecal-oral route. As noted by legendary bee virologist Dr. Leslie Bailey, bees have strong immunity to infection through the gut. But varroa, by injecting virions directly into the bloodstream of the bee (especially the pupae), changed all that. And then, as evidenced by Dr. Stephen Martin’s analysis of DWV evolution in the Hawaiian Islands [7], at least that viral quasispecies rapidly evolved to take advantage of the new vector. I suspect that the Kashmir Bee Virus family evolved similarly.

Had we beekeepers simply stood aside and allowed nature to take its course, our bees would fairly quickly have evolved resistance to varroa (as evidenced by the rebound of feral populations), due to the genetic diversity of the original bee population (contrarily, the entire inbred population of bees on California’s Santa Cruz Island was quickly extirpated by varroa [8]). But all commercial beekeepers would have gone out of business, agriculture would have suffered, etc. That simply wasn’t going to happen.

So as with any other agricultural industry, we fought the new pest with pesticides. But this only bought us time—it was not a long-term solution. The good news is that in the ensuing thirty years, both natural mutation and brutal selective pressure, as well as human-directed selective breeding, have now increased the frequency of traits for mite resistance, especially in the feral population.

We now stand at a point in time in which our common beekeeping practices have become a self-perpetuating hindrance to the natural course of evolution of mite-resistant bees. With the impending failure of amitraz, commercial beekeepers are going to be forced to shift to a Plan B for varroa management. I’ve personally been practicing such methods for some 16 years, and although practical, they are time consuming, expensive, and more difficult than simply tossing a couple of strips into each hive a few times a year.

What’s Held Up Our Adoption of Resistant Stock?

It’s now been nearly 30 years since varroa made its way to North America. Yet the majority of us are still using stopgap chemical (synthetic or natural) measures to control the mite. This is ridiculous! Selected honey bee stocks have time and again demonstrated their ability to control the mite on their own, yet we continue to breed stock that even with multiple treatments a year, still often hang on the verge of collapse.

I feel that it’s time for our industry to get serious about selecting and propagating mite-resistant bees. I subscribe to the California Farm Bureau newspaper UC Davis’s California Agriculture magazine. Both of them report on the regular release of agricultural cultivars bred for resistance to one disease or another—each strain eagerly and rapidly adopted by the appropriate growers (I do the same in my home garden and orchard). One would think that this would also be the case for bee stocks.

I can understand the frustration of the hard-working scientists at the Baton Rouge Bee Lab [9], who have long asked me why our industry has not wholeheartedly adopted their VSH or Russian stock. But as a commercial beekeeper, I can also understand why. A number of reasons come to mind:

- The stocks are “different” than the commercial stocks to which they are accustomed, and production queens have not been readily available for sale in purebred form.

- Some beekeepers who experimented with early releases may have had unfavorable experiences (although it was made clear at that time that such release was intended only to kickstart beekeeper breeding programs).

- The mite resistance of both stocks is rapidly diluted in subsequent generations if they are mated in a non-resistant drone population.

- it’s not gonna happen until our industry demands it from the breeders, who unfortunately have little incentive to do the extra work so long as the supply of queens continues to fall short of the demand for any queen available.

- Breeders are loathe to let go of their excellent and well-proven existing queen lines, and it would be both a major gamble, and take considerable effort to shift their drone populations and find isolated mating yards in which they could propagate resistant stock.

- And even if they went to the effort, they don’t want to risk pissing off large customers with a stock that doesn’t live up to its promises.

- In my experience, the existing resistant stocks will still require at least one treatment (if not two) during a season of high production, since commercially managed hives are brood factories, and brood equals varroa food. A mite-resistant colony might do fine in a small hobby apiary with minimal management, but would require treatment if stimulated for maximum broodrearing from before almonds ‘til the end of the season. And if you’re gonna have to treat anyway, why not just stick with the tried and true?

- But the main reason is that no one ever wants to change until circumstances force them to do so. These past years it’s simply been easier and more profitable to continue with highly-productive commercial stock, managing varroa with (“off label” [10]) applications of inexpensive and effective synthetic miticides.

It is this last reason/excuse that I suspect is about to change. When amitraz fails, if no cheap and effective treatment materializes to take its place [11], the impossible will suddenly become the norm. Several of the above good reasons/excuses will no longer apply. Let me make clear that I’m no Chicken Little, and the sky is not about to fall. Professional beekeepers are incredibly resourceful, and I have no doubt that most will figure out ways to survive without amitraz—indeed, many of us already have.

But when (it’s just a matter of time) amitraz fails to control mites adequately, mite management will likely become a more onerous burden for many. And that may finally bring us to the tipping point at which the large queen purchasers start to demand better mite resistance from the breeders. Luckily, due to hard work by many (mostly smaller scale) beekeepers and researchers, we’ve got some promising stock to work with. With luck, Sisyphus will finally push that damn boulder over the hill, and our bees will take over the responsibility of managing their own mites.

A New Series

To that end, this article begins a new series to follow my previous (and exhausting) progression of articles on understanding colony population dynamics. I can’t yet say for sure (since I write these articles in the morning before heading to the bee yards, or typing after work with propolis-covered fingers [12]) but I plan to cover the biology and math involved in varroa buildup and decline over the course of the season, to detail varroa’s Achilles heel, and to explain how with better understanding of evolution and biology, “treatment free” beekeepers can shift from being part of the problem to part of the solution, give suggestions for practical local or large-scale breeding programs for mite resistance, and detail the results of my recent research into the most effective ways to manage mites without the use of synthetic miticides during the interim. Get ready for a ride!

Acknowledgements

As always, I wish to express my appreciation to Pete Borst for his help in research, as well as his critiques and questioning.

Notes and Citations

[1] Before we recognized that it was actually a different species of mite, we called it at that time Varroa jacobsoni.

[2] Partially due to my own hubris of thinking that I could breed a varroa-resistant mite as easily as had I bred them for resistance to chalkbrood, AFB, and the tracheal mite.

[3] I don’t have any particular grudge against synthetic miticides, but still stinging from the rapid failure of fluvalinate, and concerned about the neurotoxicity of coumaphos, I decided to get off the synthetic miticide track. I was also concerned about persistent residues in my combs, and have taken advantage of the selling point of “chemical free” hive products. Coumaphos then quickly failed, and I suspected that amitraz would quickly follow course. Once bitten, twice shy.

[4] The Evolution of Bacteria on a “Mega-Plate” Petri Dish https://www.youtube.com/watch?v=plVk4NVIUh8

[5] Such as flumethrin, although cross resistance due to exposure to fluvalinate is highly likely. The quick recurrence of resistance to any pyrethroid or organophosphate would be expected.

[6] These hold great promise, and a number of researchers are working on them.

[7] Martin, SJ, et al (2012) Global honey bee viral landscape altered by a parasitic mite. Science 336(6086): 1304-1306.

[8] http://iws.org/CISProceedings/7th_CIS_Proceedings/Wenner.pdf

[9] Notably Drs. Tom Rinderer, John Harbo, Jeff Harris, Bob Danka, and Jose Villa—three of whom have now retired from the Lab.

[10] “Off label” is the polite term for unapproved and illegal use of miticides registered for agricultural use.

[11] Oxalic acid is the current darling, either vaporized or dissolved in glycerine, which I hope to cover next month (please don’t email me yet for details).

[12] I’m typing this article in airport lobbies and hotel rooms during a speaking visit to Ireland and the Isle of Man.