Testing Cotton Matrices for OAE

TESTING COTTON MATRICES FOR OAE

Randy Oliver

ScientificBeekeeping.com

First published in ABJ January 2023

I continue to look for improved methods for application of extended-release oxalic acid (OAE), and thought that perhaps there might be an inexpensive, fully biodegradable all-cotton fabric that might do the trick.

Chipboard (cardboard) strips work well for hung-over-the-frame application of OAE, but it takes a lot of time to insert enough of them to attain good efficacy, plus they need to be repeated. I’ve already found that Swedish cellulose sponges work very well for top bar application of OAE, but they’re kinda pricey. Cotton looked promising in some of my preliminary testing last season, so I decided to follow up on absorbent cotton fabrics.

THE FABRICS TO TEST

Having little familiarity with what sorts of cotton fabrics are available, I checked online, at fabric stores, and in thrift shops. Many cotton fabrics also contain polyester, but since such plastics are not easily biodegradable, I stuck with 100% cotton only.

I finally came up with three such fabrics to test (Figure 1) — terrycloth, sweatshirt fleece, and (at the suggestion of beekeeper who had used it successfully) cotton batting. I ordered several different battings for preliminary testing, and found one (Pellon Wrap-N-Zap) that had enough fiber strength to hold together during handling, was 100% cotton, and very inexpensive in bulk. I had high hopes that I’d found the ideal matrix!

Fig. 1 End views of the three tested cotton matrices, compared to a Swedish sponge. I found out that it is very difficult to find a pure cotton sweatshirt fabric, so the one that I tested was thinner than I’d hoped for.

PREPARATION

I cut 10 pads of each fabric, all to the same dimensions as a half Swedish sponge, weighed them, and then saturated them at the same time from a single batch of heated oxalic-glycerin solution (Figure 2).

Fig. 2 I cut all the pads to match the dimensions of Swedish sponges cut in half. After sitting overnight, the batting pads (at bottom) showed some irregularity of saturation on their surfaces, but their handling characteristics were OK once the oxalic crystallized.

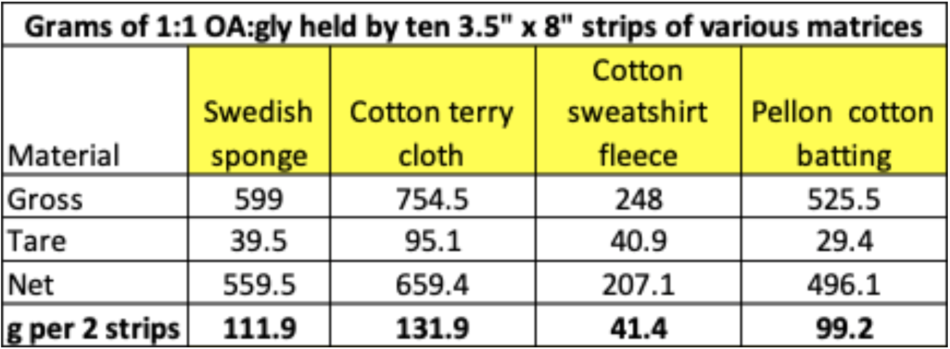

I then reweighed the pads to determine the average absorption of OA solution by each matrix, so that I could compare it to that of the sponges (Table 1).

Table 1 Absorption of oxalic-glycerin solution by the matrices. Compared to the sponges, terrycloth held more solution, the batting about the same amount, but the sweatshirt fabric far less.

I had really hoped that the batting would be the dream matrix that I’ve been looking for: cheap, biodegradable, no additives. Unfortunately, I found that this batting was initially resistant to the absorption of water or glycerin (Figure 3).

Fig. 3 The cotton batting looked ideal, until I dribbled it with water. Unlike the Swedish sponges or terrycloth, which are treated for rapid absorption of water, the batting was not, and took substantially longer to wick up the heated oxalic-glycerin solution (strike one against it).

A FIELD TRIAL

We had a couple of yards of colonies in late May with moderate to high mite counts, so we took starting mite wash counts, and randomly assigned the different matrices, blocked by starting mite count (Figure 4).

Fig. 4 On 20 May we applied the pads to double-deep medium-strength hives, replicated in two different yards (which turned out to be a good decision). Here are the pads laid out on top of the hives in Yard D before application. We left the colonies alone, and took final mite counts on 25 July (66 days later).

RESULTS

As is often the case in field trials, we got differing results in the two yards (which is why it is always best to replicate trials). To our surprise, some of the hives with the highest starting counts (28, 31, 42, 49, and 63 mites per half cup of bees) in Yard D collapsed, equally in all treatment groups.

Practical note: In our previous trials in which we applied OAE treatments later in the season, they’ve always managed to turn even very high mite infestation rates around and save the colonies. On the other hand, the few times that I’ve applied OAE treatments to high-mite colonies in the springtime, some of them have collapsed. I don’t know whether that means anything, so as they say, “Further testing is necessary.”

None of the colonies collapsed in Yard L, likely because they had also started with lower mite counts. But there were other differences between the two yards:

- The colonies in Yard L had enjoyed a good nectar and pollen flow, and gained weight. At the end of the trial, all the matrices looked moist on their upper surfaces, and after a light touch with my fingertip, I was able to taste strong acidity. When I placed samples of the spent matrices into zipper lock bags, there were droplets of oxalic solution on the insides of the bags.

- In Yard D, on the other hand, the landscape looked drier. There had been very little honey flow, the colonies were weak, and the surfaces of all the matrices — other than the sponges — were not looking moist. When I touched them with a fingertip, I did not detect as much acidity. And when I placed samples of spent matrices into zipper lock bags, no droplets showed.

Practical application: The differences in the appearances of the upper surfaces of the matrices in the two yards really stood out. The main difference between the yards that stood out was that Yard D was drier and enjoyed less nectar flow, but I have no idea why that would cause there to be less OA-glycerin solution on the upper surfaces of the matrices, since our tests in previous years have been run under very dry conditions. Why the cotton matrices would perform differently than the Swedish sponges I don’t know.

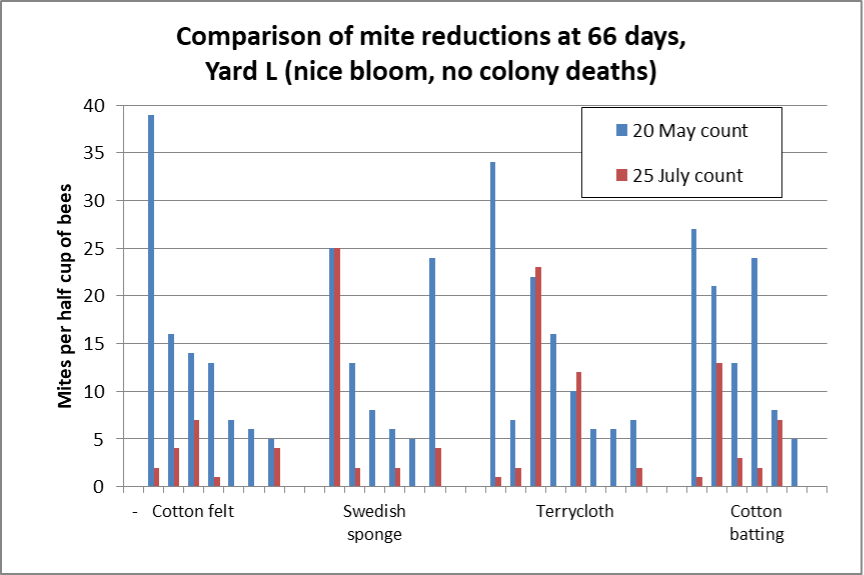

As far as mite reductions after the treatments, the yard-to-yard differences were also substantial, and strongly correlated with how “dry” the matrices appeared. Mite control was good for all matrices in Yard L (Figure 5).

Fig. 5 Mite control was good for all matrices in Yard L. I didn’t run untreated controls, so can only show starting (blue) and ending (red) mite counts for each colony. There were similar mite reductions for all matrices: median reductions 92% for the cotton felt, and 84% for all three of the other treatments.

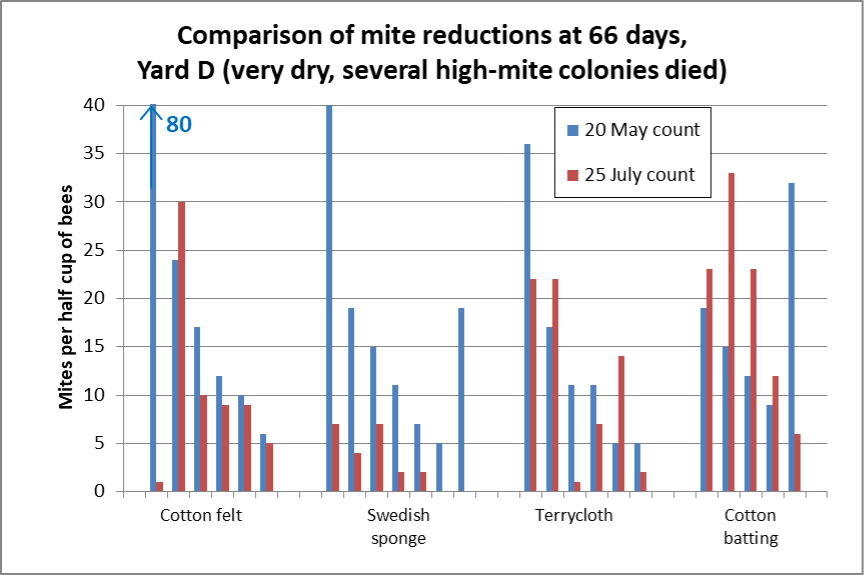

It was a different story in Yard D (Figure 6).

Fig. 6 The median reductions for the surviving colonies were not nearly as good in this yard, as indicated by the greater amount of red showing. Median mite counts actually went up for the cotton batting, and the median reductions were 21% for the felt and 38% for the terrycloth. The only matrix that worked well in this yard was the sponges, which exhibited a median reduction of 82%.

DISCUSSION

These results were a great surprise to us. I dare not attempt to explain why some of the treatments failed in Yard D, since later in the season, when conditions were dry, OAE across the rest of our operation (applied on shop towels followed by Maximizer pads) provided excellent mite control.

The sponges were clearly the standout for success (we didn’t include Maximizers, which I suspect would have performed similarly). But the abject failure of the cotton matrices in general (and especially the batting) in Yard D have soured me on cotton fabrics.

I’ll continue to test other inexpensive matrices. If you have had success with a biodegradable matrix that does not contain questionable additives (check the product’s Material Safety Data Sheet), please let me know.

I’m hearing positive feedback on OAE from all over, and will soon be writing more about my research this past season.