Thymol — A new application method? Part 2

The optimal release rate and placement of thymol 1

Thymol — A new application method?

Part 2

First published in ABJ in December 2022

Randy Oliver

ScientificBeekeeping.com

I do a lot of experimentation in beekeeping, often triggered by questions or ideas from other beekeepers. This spring a beekeeper showed me a homemade thymol concoction, which reminded me to pick back up on some previous thymol research of my own.

Extended-release thymol

Last month I raised the question of whether we could use a ½” thick cellulose matrix (Homasote [[1]]) in order to throttle the evaporation rate of a thymol treatment over a longer period of time, thus allowing us obtain efficacious mite reduction with only a single application.

A scientific note: Before investing time in large-scale controlled trials, I generally first perform some preliminary “quick and dirty” experimentation, as detailed here [[2]]. Not needing to follow a rigid protocol, this opens the door for ad hoc experimentation and unanticipated discoveries, which may then lead me in new directions.

The optimal release rate and placement of thymol

I’ve mentioned that bees don’t care for the odor of thymol, and if a treatment is placed above the cluster, they may build a wall of propolis around it (Figure 1).

Fig. 1. If the bees are unable to remove a substrate with a strong odor of propolis, they will attempt to cover or wall it off with a layer of propolis. Of interest, I did not observe any colony doing this with the Homasote blocks.

Practical note: A strong thymol treatment applied within the cluster can be very disruptive to the colony, causing the bees to noisily attempt to fan the odor away, uncap and remove brood (with lots of white pupae showing up on the bottom board), or in the worst case, the colony may completely abscond from the hive.

I found that it’s not just the dose, but rather the amount of surface area from which the thymol (with its low vapor pressure) is able to evaporate. Thus, application by thymol-saturated shop towels, with their large surface area relative to volume, results in too rapid release of the thymol (especially when applied between the brood chambers, due to the bees intensely fanning air over the towel surfaces).

Thymol on a shop towel would be a “flash” treatment. On the other hand, the registered thymol formulated products apply thymol in an extended-release manner.

Practical application: But even those products require at least two applications. So I wondered whether in order to save the labor involved in reapplication, is there a way to prolong the release of a larger dose?

What’s The Optimal Dose?

Thymol can be applied as a flash treatment to broodless colonies, with most mites dropping within a few hours of application. Chiesa [[3]] sprinkled 1 gram of powdered thymol over the tops bars of broodless colonies, four times, at 2-day intervals, and obtained over 95% mite kill, especially if the powdered thymol was mixed with powdered sugar. So 4 g of thymol appears to be enough to kill the mites in a colony not containing brood.

But when colonies contain brood, it apparently takes a larger dose, delivered over a period of weeks rather than days. Let’s take a look at the number of grams of thymol per dose of the registered products (the red numbers in Table 1).

| Table 1. The per-application dose of registered thymol formulated products. | ||||

| Product name | Dose of thymol per application | Retreatment interval and number of applications | Delivery matrix | Other ingredients |

| Apiguard | 12.5g for full-strength colonies, half that when temperature is above 77°F | Repeat at 1-2 week intervals for 4-6 weeks | Polyacrylate “gel” in water | None |

| ApiLifeVar | 8g | Repeat 3x (some instructions say 4x) at 7-10 days |

Vermiculite | Eucalyptol, menthol, and camphor |

| Thymovar | 15g can be ramped up in hot weather | Remove after 3-4 weeks, pause for 1 week, then reapply | Cellulose sponge | None |

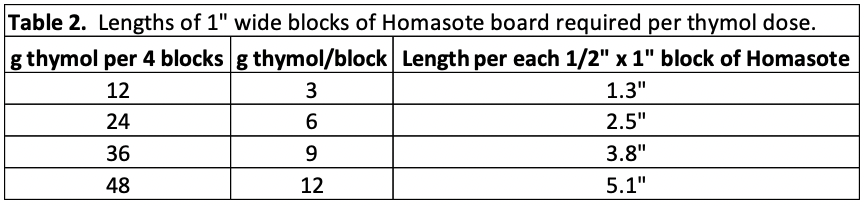

It looks as though a colony with brood can handle 6-12 grams of slow-release thymol per week. Since I’d already determined that 5.1 square inches of Homasote will hold 12 g of thymol (after absorbing a saturated solution of thymol in ethanol), it was a simple matter to precut blocks of Homasote to hold any dose of thymol that I wanted to test. I decided to apply four blocks of Homasote per hive, so I calculated how large to cut each block to attain each desired dose per hive (Table 2).

Our Field Testing

It was late August when we started this project, so unfortunately when I asked my sons as to the availability of colonies with high mite counts in which I could test these experimental thymol treatments, they said that all their 1500 colonies had the mites well under control, with mite wash counts (per half cup of bees) in the 0-2 range. This was good for them, but bad for me.

So the only colonies with high enough mite levels to use for testing were the hives left in three yards in which Rose and I had previously tested formic and oxalic treatments, some of which still had measureable mite infestations. So we started testing to see how the colonies reacted, in hot weather, to having a 12-gram dose of thymol placed right between the brood chambers (Figure 2).

Fig. 2. My assistant Rose Pasetes (wearing proper protective gear against the sun) showing the placement of four blocks (this photo is of a moderate dose). The bees initially moved away from the fumes, so it’s not obvious in this photo that the hive was full of bees and brood.

We applied the 12-g dose to six hives. To our great surprise, within a day the bees acted as though the thymol wasn’t even there. We could smell the fumes when we opened the hives, but there was no fanning, and no apparent effect upon broodrearing (Figure 3).

Fig. 3. Again, a higher dose, but showing the lack of disturbance to the bees in this freshly-opened hive.

Surprised and emboldened by the lack of bee response to the 12-g dose, we applied 24-g doses to seven colonies, some with the blocks applied between the brood chambers, some in a rim above the second brood chamber (Figure 4).

Fig. 4. Typical placement of thymol blocks in a rim.

I opened the colonies regularly to inspect for the sort of brood disruption I was accustomed to seeing during a thymol treatment, but even with the 24-gram dose I didn’t see anywhere as much as I expected. So what the heck — we made up some more blocks in order to apply 36-g doses to seven additional colonies.

During this ongoing experimentation, I was able to observe what the bees did as the intensity of the thymol fumes wore off in the first hives. As I’d noted in my experiments in 2017, most colonies began chewing away at the blocks, rather than propolizing them over (Figures 5 & 6).

Fig. 5. The blocks still smell of thymol after three weeks, but the bees don’t appear to be bothered by it by that time. Once the thymol fume intensity diminished, the bees in most of the hives started chewing away at the blocks. There were of course large colony-to-colony differences in the amounts of propolization and chewing removal, but this photo is typical.

Fig. 6. Note how where evaporation was inhibited by the blocks being squeezed between the top and bottom bars, that there was chewing only on the edges.

What surprised me most about this experiment was how little the colonies appeared to be bothered by these high-dose treatments. There was no noticeable fanning, and after an initial suppression of the rearing of young larvae, most colonies quickly resumed the rearing of all stages of brood in the center frames — no matter whether the blocks were placed between or above the brood chambers.

I was even bold enough to apply 48 grams of thymol, in a rim, applying the treatment to a strong double on 27 July, with temperatures often in the high 90sF (Figures 7 & 8).

Fig. 7. Photo on 17 August — 21 days after application of four 12-gram thymol blocks — of healthy brood of all ages in the lower brood chamber in the heat of summer drought. The solid sealed brood indicated that the larvae had been started and reared during the most intense period of thymol evaporation. I could hardly believe my eyes! The mite wash count had gone from 14 mites to zero.

Fig. 8. Same colony on Oct 9, 74 days after application of blocks (total 48g of thymol), which by then had no noticeable thymol odor. The mite wash count was still zero, with the colony containing plenty of good-looking brood and honey.

Surprised and emboldened by how well this colony did with 48 grams of thymol placed in a rim (and needing more data for a dose-response curve), in late September I identified two (unfortunately) weak colonies with measureable mite counts, and placed four 12-g blocks between the brood chambers (Figure 9). Weather was in the 70sF, but soon rose again to the 90s. Unfortunately the nectar and pollen flows were over, and there was little broodrearing taking place before or during this intense treatment, but I wanted to see (1) whether a 48-gram dose would zero out the mite counts as it did with the colony above and (2) to see how weak colonies would respond to this extremely high dosage of thymol.

Fig. 9. A weak colony four days after application of four 12-g thymol blocks late in the season (an intentionally intense test). Due to dearth there wasn’t much brood when I applied the blocks, but even after four days of this intense exposure, there were still patches of brood of all ages on three frames in the upper box. Other than their immediate buzz when I had first applied the strips, the bees did not appear to be disrupted by the obvious odor of thymol – the bees appeared to be acting “normally.”

I’m not about to say that there was no adverse effect from this strong dose upon the colonies, but I was surprised by how the bees appeared to quickly acclimate to the odor of thymol in the hive (it was easy for me to smell when I opened them). These two weak 48-gram colonies continued to rear some brood of all ages throughout the treatment, and their mite wash counts had dropped to zero by 17 days after application (one going from a count of 44 mites to zero).

The Dose-Response Curve

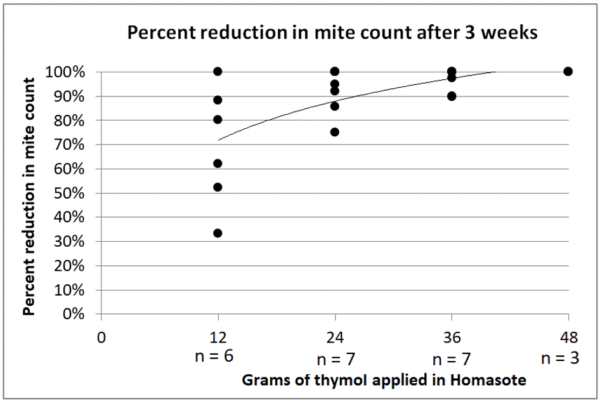

I was only able to find 23 colonies with mite counts high enough on which to test this method of thymol application (having starting mite wash counts ranging from 5 to 44; mean 20, median 18), so this data is only preliminary and suggestive. In order to estimate a dose-response curve, I calculated percent reduction of the counts vs. the applied dose of thymol, so that I could get an idea as to the optimal dose to test next season (Figure 10).

Fig. 10. The higher the data points, the better the mite reduction — 100% indicates and ending count of zero. A 12-gram dose (divided between 4 blocks) gave inconsistent mite reduction, but 48 grams zeroed the counts in all three hives. The less-intense 36-gram dose may be the optimal target dose, but it’s not yet clear whether it is best applied between the brood chambers or in a rim above (I tested both).

Discussion

As a long-time user of Apiguard, I’m pretty stoked by the convenience of this application method of thymol in Homasote blocks. I was dumbfounded by how gentle the 12- and 24-gram doses applied in this manner were on the bees and brood, and pleasantly surprised by how well the colonies handled the 36- and 48-gram doses. I plan on obtaining a permit to expand my testing of this method next season.

Practical application: An easy-to-apply thymol treatment that requires only a single application would be great to use in rotation with oxalic and formic acid.

Note: This application method is not approved in the U.S, but could be used by beekeepers in New Zealand or other countries where it is legal.

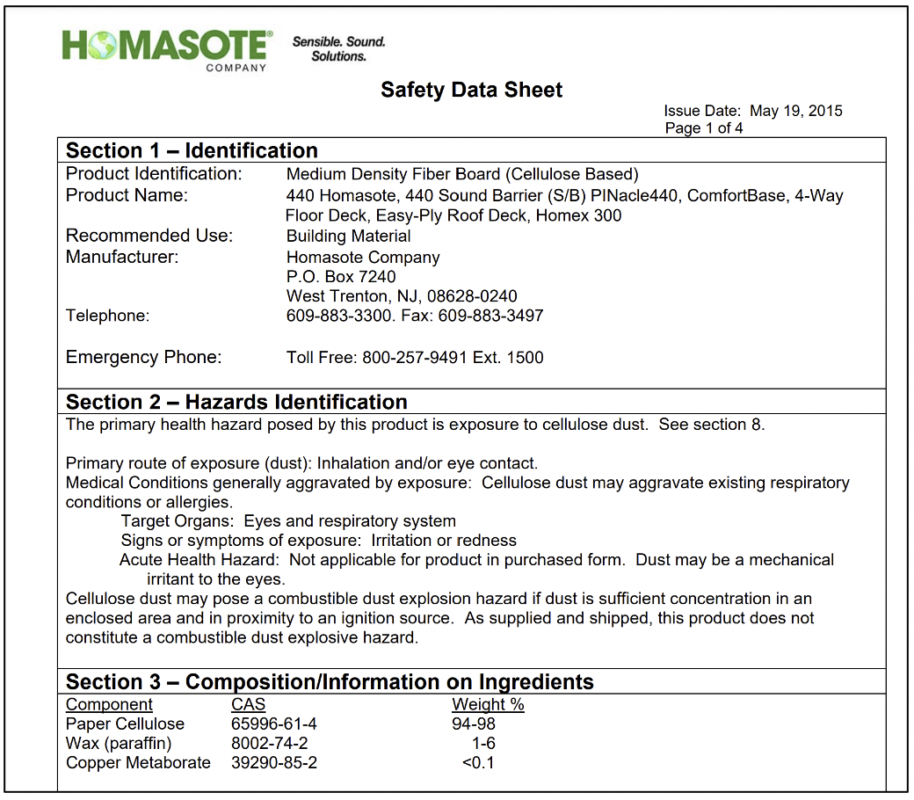

Addition: Checking the Safety Data Sheet for Homasote, I find that it contains a tenth of a percent (1000 ppm) copper metaborate (likely to inhibit mold and termites).

So this raises the question as to whether that amount of copper metaborate is of concern as far as adverse effects upon the bees, or contamination of honey (unlikely, since we don’t normally apply thymol treatments during a honey flow).

The EPA concluded in 2009 that “Available data from a honey bee acute toxicity study indicated that copper is practically nontoxic to honey bees.” (https://www3.epa.gov/pesticides/chem_search/reg_actions/reregistration/red_G-26_26-May-09.pdf), apparently based upon a single study:

Hoxter, K. (1988) Copper Hydroxide: An Acute Contact Toxicity Study with the Honey Bee: Wildlife International Ltd. Project No. 190- 140. Unpublished study prepared by Wildlife International Ltd. 14 p.

A point to keep in mind is that it’s unlikely that a bee would consume any of the Homasote. I did not observe any indication of adverse effects after treatment, but will run some cage trials.

Hladun, K.R., Di, N., Liu, T.-X. and Trumble, J.T. (2016), Metal contaminant accumulation in the hive: Consequences for whole-colony health and brood production in the honey bee (Apis mellifera L.). Environ Toxicol Chem, 35: 322-329. https://doi.org/10.1002/etc.3273

Citations and notes

[1] http://www.homasote.com/assets/files/homasote-440-sds.pdf

[2] For this off-label experimentation with thymol, I obtained a Pesticide Research Authorization from the California Department of Pesticide Regulation, since unlike with my previous research that did not involve using thymol as a miticide, in this case I was using it for that purpose.

[3] Chiesa, F & M D’agaro (1991) Effective control of varroatosis using powdered thymol. Apidologie 22(2): 135-145.